The Byford Dolphin accident remains one of the most devastating incidents in the history of offshore oil and gas operations. This tragic event, which occurred on November 5, 1983, serves as a stark reminder of the dangers faced by workers in high-risk industries. The incident not only claimed multiple lives but also highlighted critical safety concerns that continue to shape offshore safety protocols today. Understanding the Byford Dolphin accident is essential for anyone interested in offshore safety, industrial risks, and the lessons learned from such tragedies.

The Byford Dolphin was a semi-submersible drilling rig operating in the North Sea, a region known for its challenging and hazardous working conditions. On that fateful day, a catastrophic failure occurred during a routine operation, leading to an explosion and rapid decompression. This event resulted in the deaths of five workers, with another suffering severe injuries. The tragedy sent shockwaves through the offshore industry and prompted a reevaluation of safety measures to prevent similar incidents in the future.

As we delve deeper into the details of this accident, it is crucial to recognize its significance in the context of offshore safety. The Byford Dolphin accident underscores the importance of stringent safety protocols, proper training, and continuous improvement in high-risk environments. By examining the causes, consequences, and lessons learned, we can better appreciate the ongoing efforts to protect workers in the offshore industry and ensure that such tragedies are not repeated.

Read also:Journey To The Center Of The Earth Unveiling The Wonders Beneath Our Feet

Table of Contents

- Biography of the Byford Dolphin

- The Fateful Day: What Happened?

- Technical Details of the Accident

- Human Factors Contributing to the Tragedy

- Safety Protocols Before and After the Accident

- Legal and Regulatory Impact

- Lessons Learned from the Byford Dolphin Accident

- Current Safety Measures in Offshore Operations

- Statistics and Data on Offshore Accidents

- Conclusion and Call to Action

Biography of the Byford Dolphin

The Byford Dolphin was a semi-submersible drilling rig designed for deep-water operations in the North Sea. Built in 1974 by Mitsubishi Heavy Industries in Japan, the rig was operated by Dolphin Drilling, a Norwegian company. Over the years, it became a key player in the offshore oil and gas industry, contributing significantly to exploration and production efforts in one of the world's most challenging marine environments.

Below is a table summarizing key details about the Byford Dolphin:

| Attribute | Details |

|---|---|

| Name | Byford Dolphin |

| Type | Semi-submersible Drilling Rig |

| Year Built | 1974 |

| Builder | Mitsubishi Heavy Industries |

| Operator | Dolphin Drilling |

| Location of Operation | North Sea |

The Fateful Day: What Happened?

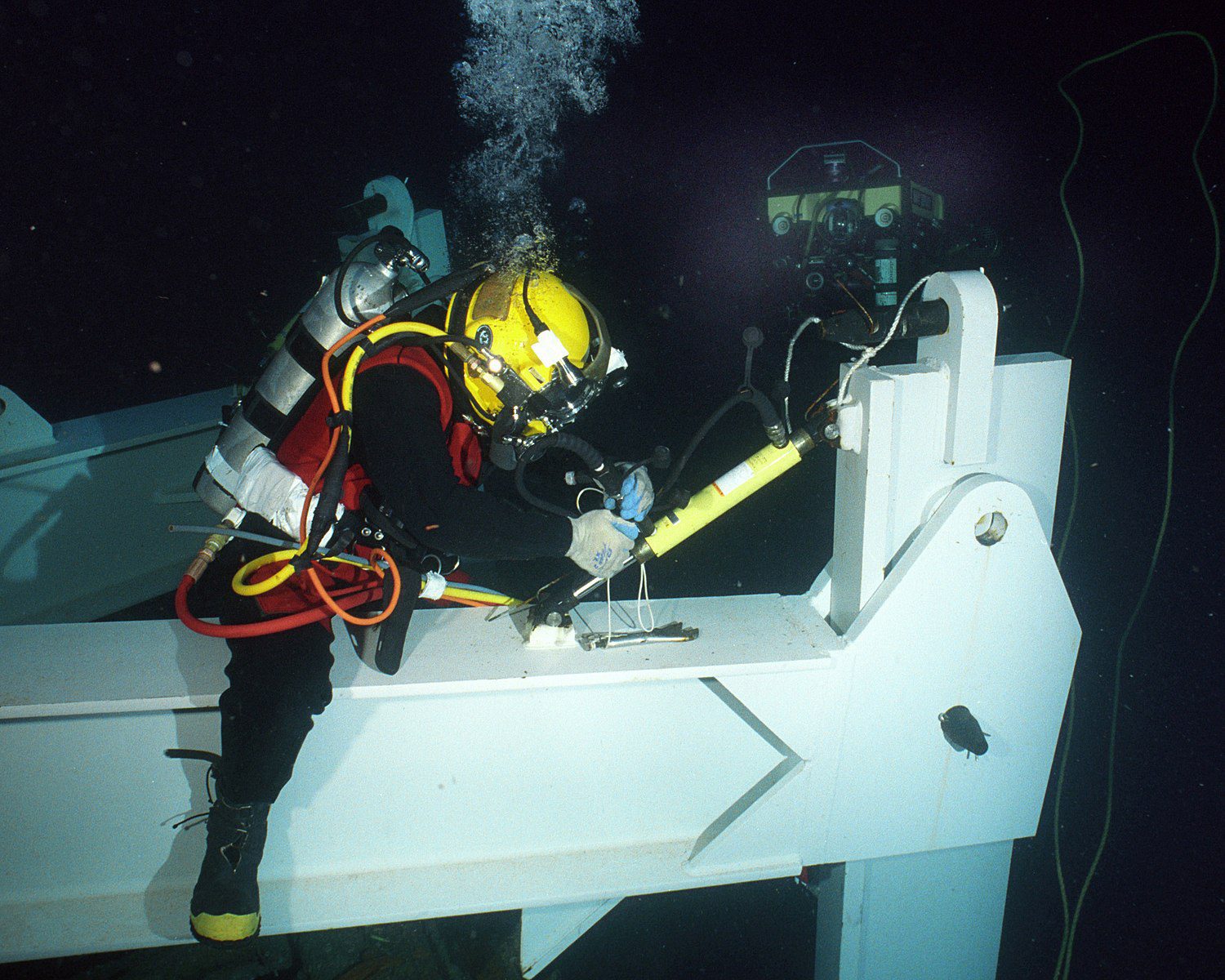

On November 5, 1983, the Byford Dolphin was conducting routine operations in the North Sea when a catastrophic accident occurred. The incident took place during a procedure known as "diving bell transfer," which involved moving divers between the rig and a diving bell. A sudden and massive decompression event led to an explosion, resulting in the deaths of five workers and severe injuries to another.

The sequence of events that led to the tragedy began with a failure in the pressure control system. The diving bell, which was designed to maintain a controlled environment for divers, experienced a rapid loss of pressure. This caused a violent release of compressed air, leading to the explosion and the tragic loss of life. The incident was unprecedented in its scale and severity, prompting an immediate investigation into its causes.

Technical Details of the Accident

The Byford Dolphin accident was primarily caused by a failure in the rig's pressure control system. Specifically, a valve malfunction allowed compressed air to escape uncontrollably, leading to the catastrophic decompression. The diving bell, which was connected to the rig at the time, experienced a sudden and extreme pressure drop, resulting in the explosion.

Experts have identified several technical factors that contributed to the failure:

Read also:Uday Chopra The Versatile Bollywood Actor Producer And Writer

- Valve Design Flaw: The valve system lacked adequate safeguards to prevent accidental opening.

- Maintenance Issues: There were indications of inadequate maintenance and inspection of critical components.

- Human Error: Miscommunication and procedural lapses may have played a role in the sequence of events.

Human Factors Contributing to the Tragedy

While technical failures were a significant factor, human factors also played a crucial role in the Byford Dolphin accident. Miscommunication between team members, insufficient training, and a lack of adherence to safety protocols were identified as contributing elements. These human errors compounded the technical issues, leading to the tragic outcome.

Communication Breakdown

One of the key issues was a breakdown in communication between the divers and the rig operators. This miscommunication led to confusion about the status of the pressure control system, ultimately resulting in the catastrophic failure.

Lack of Training

Some workers involved in the operation were reportedly not adequately trained to handle emergency situations. This lack of preparedness further exacerbated the situation, as critical decisions were made without a full understanding of the risks involved.

Safety Protocols Before and After the Accident

Prior to the Byford Dolphin accident, safety protocols in the offshore industry were already in place but were not as comprehensive as they are today. The tragedy exposed significant gaps in these protocols, prompting a major overhaul of safety standards across the industry.

Pre-Accident Safety Measures

Before the accident, safety measures focused primarily on equipment maintenance and basic operational guidelines. However, these measures were not always rigorously enforced, and there was a lack of emphasis on human factors and emergency preparedness.

Post-Accident Reforms

In the aftermath of the Byford Dolphin accident, the offshore industry implemented several key reforms:

- Enhanced Training Programs: Workers now undergo more rigorous and comprehensive training to handle emergencies.

- Improved Equipment Design: Critical components, such as valves and pressure control systems, have been redesigned for greater reliability.

- Stricter Regulations: Governments and regulatory bodies introduced stricter safety standards and oversight mechanisms.

Legal and Regulatory Impact

The Byford Dolphin accident had far-reaching legal and regulatory implications. It prompted investigations by multiple authorities, including the Norwegian government and international bodies. These investigations led to the introduction of new laws and regulations aimed at improving safety in offshore operations.

Key Legal Outcomes

Several legal actions were taken in response to the accident:

- Criminal Charges: Some individuals and companies involved in the operation faced criminal charges for negligence.

- Compensation Claims: Families of the victims filed compensation claims, leading to significant payouts.

- Policy Changes: Governments introduced new policies to ensure better oversight and accountability in offshore operations.

Lessons Learned from the Byford Dolphin Accident

The Byford Dolphin accident serves as a powerful reminder of the importance of safety in high-risk environments. Several key lessons have been learned from this tragedy:

- Importance of Communication: Clear and effective communication is essential to prevent misunderstandings and errors.

- Need for Continuous Training: Regular training and drills are crucial to prepare workers for emergencies.

- Focus on Equipment Reliability: Critical systems must be regularly inspected and maintained to ensure reliability.

Current Safety Measures in Offshore Operations

Today, the offshore industry has implemented numerous safety measures to prevent accidents like the Byford Dolphin tragedy. These measures include advanced monitoring systems, improved equipment design, and comprehensive training programs for workers.

Technological Advancements

Modern offshore rigs are equipped with state-of-the-art technology to monitor pressure systems and detect potential failures. These advancements have significantly reduced the risk of accidents in recent years.

Regulatory Oversight

Governments and regulatory bodies now play a more active role in ensuring compliance with safety standards. Regular inspections and audits are conducted to identify and address potential risks.

Statistics and Data on Offshore Accidents

According to data from the International Association of Oil & Gas Producers (IOGP), the number of offshore accidents has decreased significantly over the past few decades. This decline can be attributed to improved safety measures and stricter regulations.

- Accident Rates: The accident rate in the offshore industry has dropped by over 50% since the 1980s.

- Fatality Rates: Fatalities have also decreased, thanks to better safety protocols and emergency response systems.

Conclusion and Call to Action

The Byford Dolphin accident was a tragic event that highlighted the dangers of offshore operations and the critical importance of safety. By examining the causes, consequences, and lessons learned, we can better appreciate the ongoing efforts to protect workers in the offshore industry. As we move forward, it is essential to continue improving safety measures and ensuring that such tragedies are not repeated.

We invite you to share your thoughts on this article and join the conversation about offshore safety. If you found this content informative, please consider sharing it with others or exploring more articles on our site to learn about similar topics. Together, we can contribute to a safer and more secure future for all workers in high-risk industries.